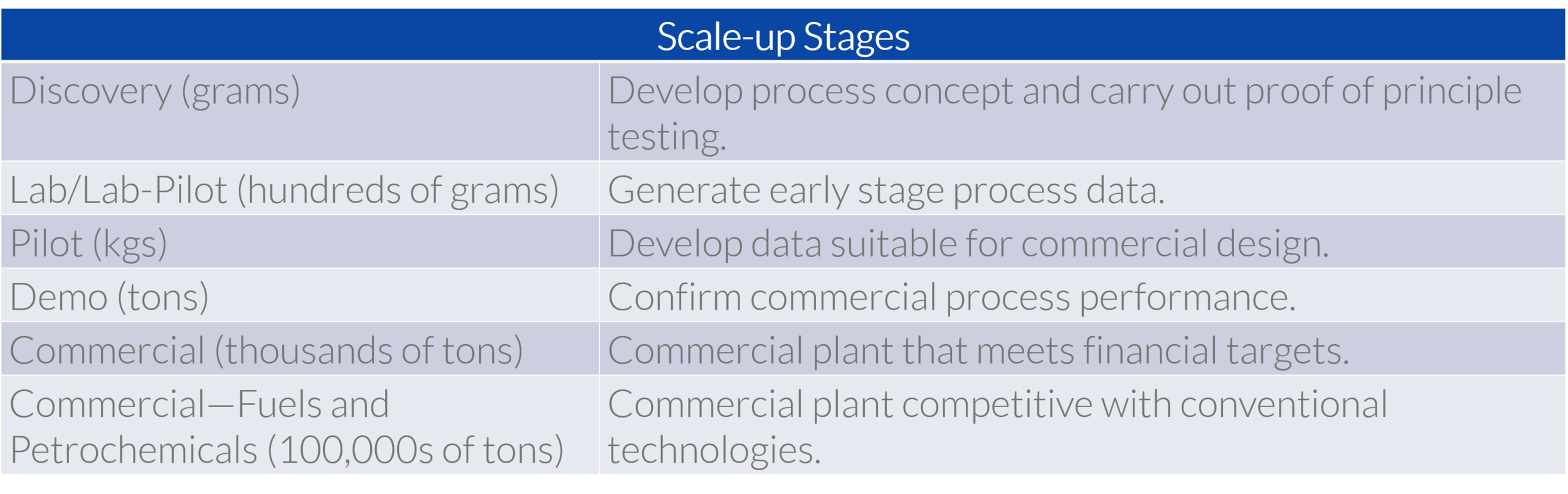

The challenges of scaling a new technology in the chemical or biological processing industries have been well documented, and I’ve previously outlined an approach to scale up efficiently to reduce the time, cost, and risk of scaleup, including thoughts on process engineering, modeling, and multi-scale data Trying to compete in the fuels and petrochemical space adds another significant challenge—the massive scale of conventional technologies. Often a step beyond that first ‘small’ commercial unit is needed just to be competitive, as outlined in the table below.

Take cellulosic ethanol as an illustrative example. Several of the larger projects that have been built have a capacity on the order of 25-50 M gallons per year, or about 75,000 – 150,000 tons/year. For those used to refining terminology, this is about 1800-3600 BPSD (barrels per stream day), orders of magnitude below world scale refineries. This is even several times smaller than a world scale ethanol plant, meaning that novel biofuels technologies must compete on 1st plant economics, with an investment of hundreds of millions of dollars, at a scale that is several times smaller than the established technology. In other words, additional scale-up is needed just to approach competitive economics. This makes it very difficult to be disruptive!

These challenges are leading many companies in this space to turn towards higher value products. Significant advances in biotechnology are creating opportunities to produce everything from chemicals like succinic acid and 14-butanediol, proteins for fish, animals, and humans, and leather, silk and meat replacements.

While often discussed as a pivot signaling the end of advanced biofuels as we know it, I see this more as a necessary detour on the road to a robust bioeconomy. A robust bioeconomy will require both commodity fuels and higher value, smaller market products. This detour takes us to projects with higher value products, and therefore better returns, at a scale that is more relevant for the product in question. At the same time this detour provides an opportunity to work through scale-up challenges, risk reduction, and industry acceptance of larger industrial biotechnology projects at this relevant scale, paving the way for the large biofuels projects and a robust bioeconomy!