Gas fermentation is a novel industrial biotechnology that can contribute to the growth of the bioeconomy by using low cost, readily available carbon sources such as methane, carbon monoxide, and carbon dioxide to produce various fuel, chemical and food products, such as ethanol, ethylene, triglycerides, proteins, and polyesters.

Figure 1: Gas Fermentation Landscape

Gas fermentation has advantages over conventional processing routes, including:

· lower cost operating conditions

· robustness to fluctuations in feed rate and composition

· tolerance to contaminants in the gaseous feeds.

We can look at two classes of gas fermentation. The first involves direct conversion of CO2 through gas fermentation, typically with hydrogen and/or oxygen as co-feeds. A diverse array of products can be produced through these routes, including triglycerides which can be used for food, materials, and fuel applications. Chemicals such as acetic acid and ethylene are other products viable through these routes, along with single cell proteins for animal feed or other alternative protein applications.

We can also consider gas fermentation routes that convert CO2 precursors, such as carbon monoxide or methane into useful products. In this case, possible products include chemicals such as ethanol, methanol, or iso-propanol, and polymers such as polyhydroxyalkanoate (PHA).

However, a key challenge with gas fermentation involves the design of a cost-effective reactor system with high mass transfer coefficients for the gaseous feedstocks into an aqueous media. A number of reactor types have been proposed to overcome this challenge, from simple bubble columns to more sophisticated air lift and external loop reactors. These reactor types have tradeoffs between mass transfer and design complexity. It is important to identify the best option for a particular gas fermentation application.

Figure 2: Mass Transfer Challenge

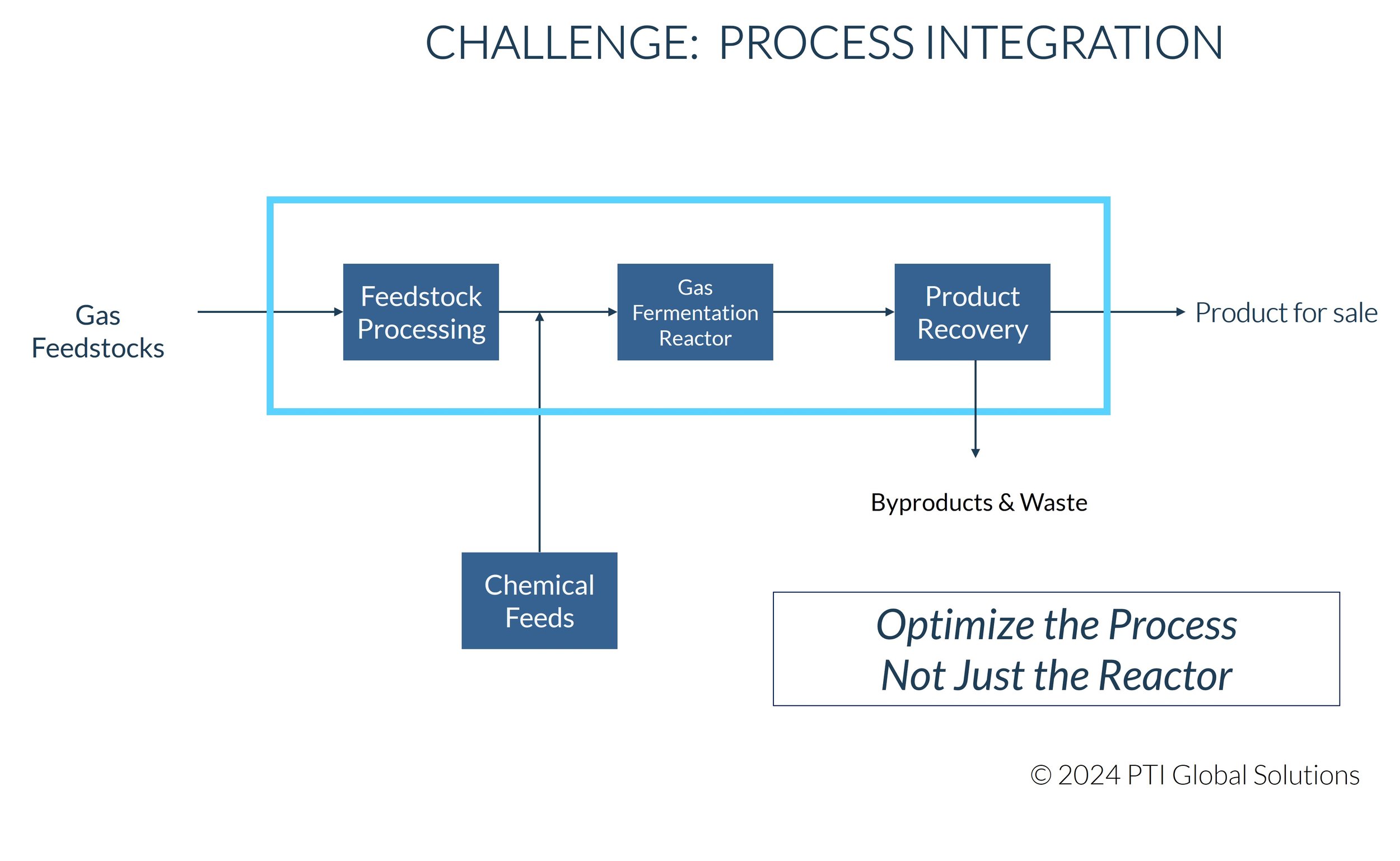

In addition, with any biological or chemical process it is important to look beyond the reactor system and consider the integrations of unit operations both upstream and downstream of the reactor system in order to optimize the process as a whole. For gas fermentation, we may need to consider tradeoffs associated with the cost of compression or gas cleanup vs potential performance benefits in the reactor system. Similarly, we need to consider the design and performance of the product recovery section. Ultimately, we want to optimize the process not just the reactor system.

Figure 3: Process Integration Challenge

Additional challenges must be addressed when scaling and commercializing gas fermentation technology. These include:

· Lack of established data and models. Compared to petrochemical reaction chemistry, the availability of data and reactor design models is quite limited.

· New equipment to be designed and constructed, such as custom fermenters.

· New separation challenges. Recovery of extracellular products such as ethanol or acetic acid from the fermentation broth, or recovery of intracellular products.

· New optimization criteria. Carbon footprint and ESG/LCA metrics in addition to traditional optimization metrics such as operating cost and capital cost.

· New microbial catalysts. As gas fermentation becomes a more mature and broadly deployed technology, methods for manufacturing and distribution of commercial scale quantities of these catalysts will be required.

As gas fermentation becomes more mature and we see more commercial applications, opportunities for future developments will enable greater scale, reduced production costs, and new products.

· Microbial modeling, including bacterial growth kinetics and flux models. By bringing a more analytical approach to our gas fermentation systems, we can enhance understanding of the biological reactor systems, and develop custom reactor designs for specific microbial systems.

· Strain development to reduce bioproduct formation, increase contaminant tolerance, and enable more extreme operating conditions (higher temperature, for example).

· Reactor design and scaleup, to develop reactor systems that can enhance mass transfer while balancing constraints around capital and operating costs.

· New or improved approaches for product recovery to reduce the cost and complexity of product separation and purification.

The future is bright for this exciting technology area. Gas fermentation will play a key role in the growth of the industrial bioeconomy in the coming decades.